OEM Manufacturer 80ton Welding Rotator Turning Roll - What Is A Welding Rotator — Weld-Max HGK 10 – Sanlian

OEM Manufacturer 80ton Welding Rotator Turning Roll - What Is A Welding Rotator — Weld-Max HGK 10 – Sanlian Detail:

Welding rotator is kind of our advanced welding equipment, which is be researched and manufactured absorbing domestic and international advanced equipment.

It is mainly used for pipe, containers, boilers, pressure vessels, oil tank and other cylinder’s assembling, burnishing and welding.

There are two series of welding rotator, including self aligning rotator (HGZ), and conventional rotator (HGK).

Welding rotators are similar to positioners, in that it’s a mechanical means to rotate cylindrical vessels.

They minimise handling, increase efficiency, and dramatically improve the quality of workmanship from welders of all skill levels.

MISA can supply conventional and self-aligning rotators to suit various sizes of weldments across a variety of sectors.

Any steelworks with cylindrical vessels, be it small diameter piping to large industrial cylindrical vessels for windtower production, a rotator will be beneficial, sometimes a necessity.

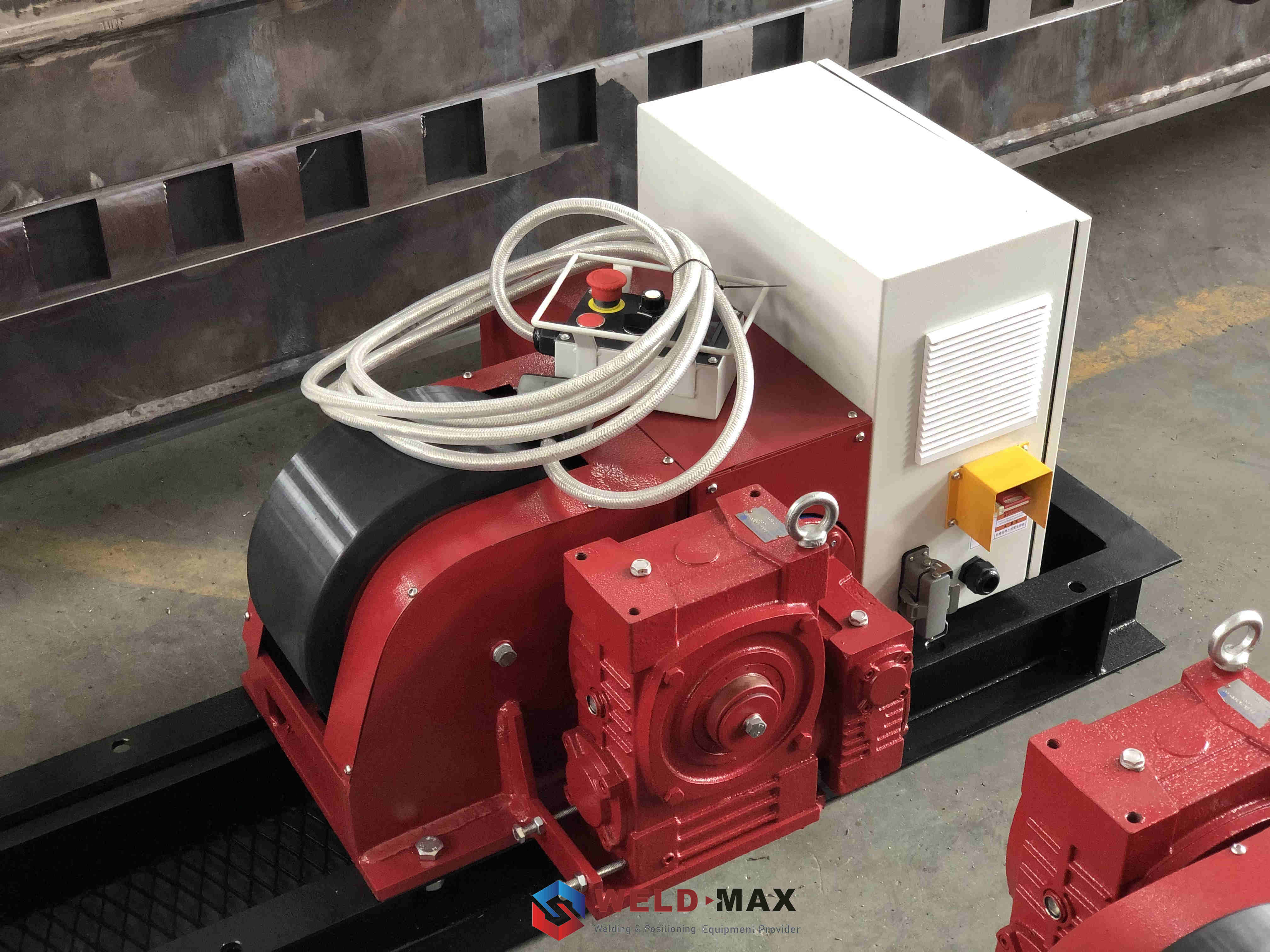

The welding rotators have trolley tilting anti drift rotator. Accordingly this decive has advantages of compact structure, small cubage, beautiful shape, ligtweight, convenient operating and so on.

The machine can assort all kinds of auto welding or manual welding, improving welding quality, lessening welding labor and improve productivity. We can provide solutions to unique welding rotator according to the customer’s requirement.

The welding rotator can use together with column and boom and SAW system to realize inside and outside girth and longitudinal welding.

Competitive Advantage:

1. All the bolt using 12.9 grade Bolt , not using 8.4 grade. Making the machine more stronger.

2. 20 % overweight design , could making the rotator focus more.

3. Double motors and reducers , and if the workpiece stress is different , could ensure the rotator working properly , and longer service life.

4. Double row wheels , not only making the wheels stable , but also artifacts to increase friction.

5. All the parts using well-known brands in China or other countries . Quality is more reliable .

6. Using double row bearings.

Product detail pictures:

Related Product Guide:

Biggest Police Union in the Country Endorses Trump | 300ton Wind Tower Welding Rotator

SunLive – Work to remove 4500m3 Waioeka Gorge slip | 50ton Bolt Adjustment Welding Rotators

We emphasize advancement and introduce new products into the market each year for OEM Manufacturer 80ton Welding Rotator Turning Roll - What Is A Welding Rotator — Weld-Max HGK 10 – Sanlian, The product will supply to all over the world, such as: St. Petersburg, luzern, Czech republic, Why we can do these? Because: A, We are honest and reliable. Our items have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It might be highly appreciated.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!