-

In many large-scale production projects, the efficiency of automation brings convenience to production. Reduce manual operation, more accurate and fast. In projects such as welding foundation pipes, wind towers, etc., automated welding is most often chosen. Common combination of automatic...Read more »

-

Shipping by sea has fully resumed in May, and our shipments are all going well. Two 20-ton standard positioners ordered by Canadian customer, we completed the delivery in 45 days! In order to cooperate with the customer’s upcoming production line, we communicated the plan and made a ...Read more »

-

Manufacturing large diameter pipes, wind towers, tanks, and other cylindrical objects is expedited with growing lines. With Weld-Max’s growing line systems, you can adjust the tank sections for fit-up and welding to fit any size work piece. Fast alignment, leveling, and fit-up are ...Read more »

-

In many production lines, the matching of welding positioner and welding column boom is common, which can improve production efficiency. Welding positioner: The purpose of a weld positioner is to position the weld in the optimal spot for welding. Various welding positioners are available from MI...Read more »

-

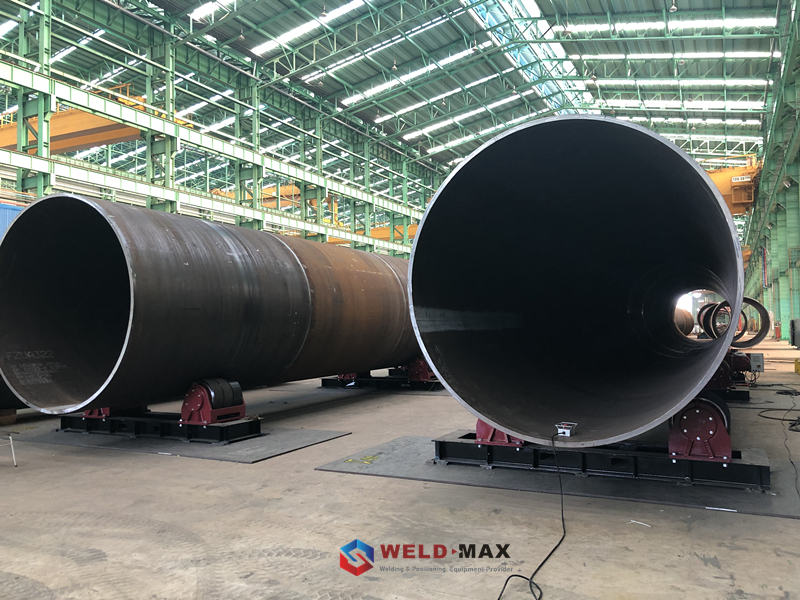

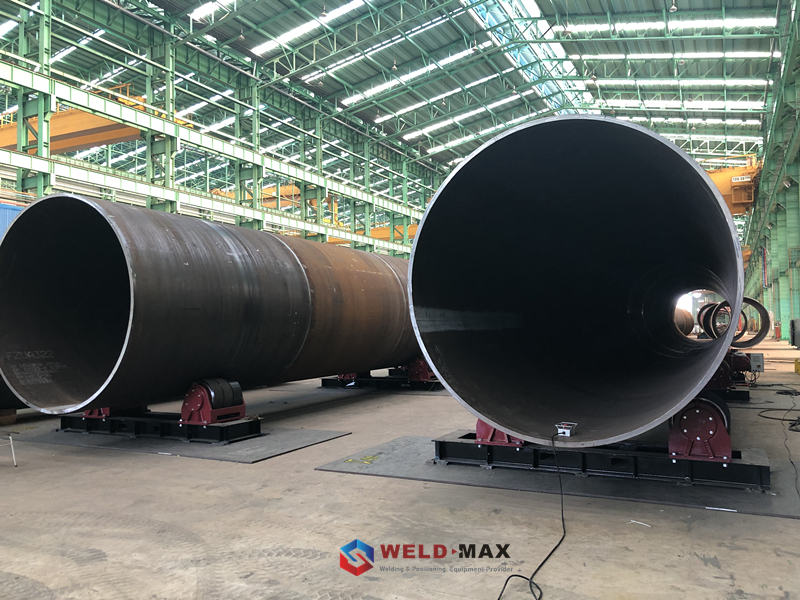

Because a welding rotator does not require lifting equipment or cranes, it increases production and reduces idling time. Welding rotators are suitable for light and heavy fabrication shops. You can achieve exceptionally high quality circumferential joints for shells by using both automatic and ma...Read more »

-

Consider a welding rotator for processing and welding heavy and round workpieces. The diameter of pipes, containers, and other workpieces can easily be adjusted on welding rotators. There are different welding rotators with capacities ranging from 1,000 kg to 500 t available from us. Depending o...Read more »

-

When selecting, operating, and maintaining a positioner, welders should consider these five suggestions, regardless of the size of the weldment. 1. Remember the center of gravity (COG) It is important not only to take the weight and size of the weldment into account when selecting a posit...Read more »

-

What is a welding rotor ( Turning Roll )? The welding rotator is an automatic tool that can weld pipes, tanks, piles and other round objects more easily. They can handle sizes from small to large, and save time by joining two moving metal sheets together, freeing up hands for welding. They can ma...Read more »

-

The Choice Of The Conventional Welding Rotator In recent years, the conventional welding rotator have been continuously rising from the perspective of sales domains. Now more and more industries will use roller racks. Why is its usage rate so high? Maybe we can try to find out why. 1. The weldi...Read more »