Today, let us understand the Welding Rotator.

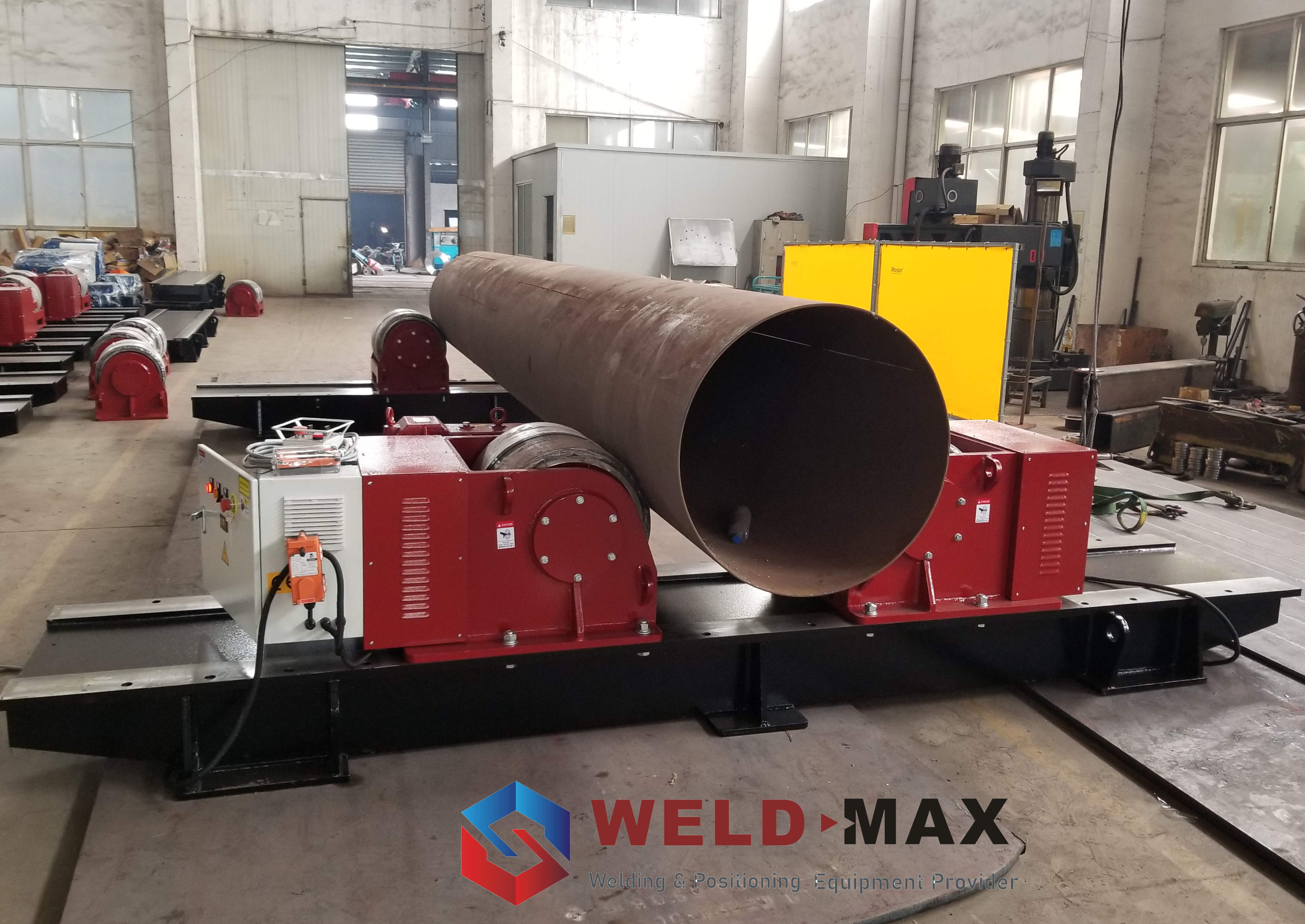

The welding rotator is a device that drives the circular weldment to rotate by means of the friction between the welding workpiece and the active roller. Welding rotator can be divided into conventional welding rotators and self-adjusting welding rotators. The welding rotator is a kind of welding auxiliary equipment, which also includes positioner and manipulator.

Here, we will mainly talk about the difference between the conventional welding rotator and the self-aligning welding rotator.

Conventional welding rotators:

The motor is equipped with a double-stage turbine and a worm reducer to drive the double-turbine of the driving frame, and the roller of the driven frame is the passive wheel.

The conventional welding rotator can move the roller set and adjust the center distance of the rollers according to the diameter of the workpiece. It is a displacement machine that drives the rotation of the weldment by means of the friction between the active roller and the weldment.

Only one main part of the conventional welding rotator is the driving roller part, and the other is the driven roller part.

The driving device adopts a variable frequency speed regulating motor, and the roller part is driven by a reducer, and the weldment is driven to perform welding rotation. The adjustment of the distance between the roller parts in each welding rotator is done manually, using positioning bolts according to the weldment.

Self-aligning welding rotator:

The swing angle of the wheel set is automatically adjusted according to the diameter of the workpiece, without manual adjustment. The combined rollers with inner steel core and polyurethane outsourcing have large load-bearing capacity and strong driving ability.

The self-aligning welding rotator has two sets of main and auxiliary machines as a set, as well as an active welding rotator and a passive welding rotator. The self-aligning series of active and passive frames have four rollers in each group, which are durable and have no vibration during use.

Automatically adjust the swing angle of the wheel group according to the diameter of the workpiece, and can automatically adjust the center. When the self-aligning welding rotator is matched with the welding manipulator and welding power source, the inner and outer longitudinal seams and the inner and outer circumferential seams of the workpiece can be welded.

The height of the main and driven rollers can be adjusted appropriately, and the assembly and welding of cones and segmented unequal diameter rotating bodies can also be carried out.

The transmission noise is low, the workpiece rotates smoothly, and the welding, polishing, rubber lining and assembly operations of the cylindrical cylinder can be realized. The rotation speed of the roller should be stable and uniform. No crawling phenomenon is allowed.

It must have over-voltage protection, self-protection functions, fault display and storage functions, automatic air switch short-circuit protection, and preset parameters.

For some non-round and long weldments, they can be clamped in a special ring clamp, and welding operations can also be carried out on the welding rotator.

The self-aligning welding rotator adopts digital adjustment and display technology for the roller speed, and the welding speed setting is very intuitive and accurate, which reduces the difficulty of operation for workers.

The manufacturing and assembling accuracy of the welding rotator shall meet the accuracy requirements of level 8. The welding rotator should be made of high-quality steel, such as a welded base, it must be subjected to stress relief heat treatment after welding.

The welding rotator must be equipped with a reliable conductive device, and the welding current is not allowed to flow through the bearing of the roller frame.

When the cylindrical workpiece is welded on the anti-axial movement welding rotator, the axial movement of the workpiece during the whole welding process should be ≤±3mm.

The center distance of each pair of rollers of the welding rotator must be adjusted according to the diameter of the cylindrical workpiece to ensure that the wrap angle of the two roller pairs is 45° larger than 110°.

The welding rotator is equipped with a 8m control cable, the wheel is reversible switch, near control, remote control switch.

Through the previous understanding of the conventional welding rotator and the self-aligning welding rotator, we realized that the main difference between the two is: the self-aligning welding rotator does not require manual adjustment, while the conventional welding rotator requires manual adjustment of the roller components in each roller rack spacing. A simple summary: self-aligning welding rotator—automatic, conventional welding rotator—manual.

So when purchasing a welding rotator, should you choose a self-aligning welding rotator or a conventional welding rotator?

It’s actually really easy. If the size of the workpiece welded by your own company is relatively fixed and the range of change is limited, such users suggest that you can choose to customize the self-aligning welding rotator, which does not require manual adjustment, which can improve work efficiency. And for the variable size of the workpiece, you can choose a conventional welding rotator.

Send your message to us:

Post time: Apr-28-2021