Weld-Max mainly produces welding and positioning equipment, such as welding rotators, welding positioners, welding manipulators (column and boom), etc.

These devices can help users more convenient and efficient in the welding process, and are very practical devices for assisting welding.

Welding Manipulator ( Column and Boom):

The welding manipulator can weld metal containers and metal welded structures in various ways such as circumferential seams and longitudinal seams. It is widely used in many industries such as wind power equipment, pressure vessels, petrochemicals, pipelines, steel structures, boilers, shipbuilding, and surfacing welding. It can be equipped with electric pallets, internal telescopic arms, manned devices and maintenance ladders according to user requirements. It can also be equipped with various tracking and monitoring, arc swing, flux recovery and transportation devices, etc. The control system of the manipulator adopts digital control mode, which is convenient for operation, precise control, and convenient for linkage control with other equipment.

The welding manipulator is generally composed of columns, beams, slewing mechanisms, trolleys and other components. Each component is a building block structure. Generally, columns and beams are the basic components, and the remaining components can be selected according to user requirements.

Unique cross-beam and column cross-section design, stress relief treatment after welding, shape by planing and grinding. Light weight, high strength and good stability. The design of the telescopic arm inside the beam can effectively increase the horizontal telescopic distance of the beam.

The beam lifting adopts AC motor constant speed method, which is stable and uniform and has a high safety factor. With safety anti-falling device.

The beam telescopic, the column electric rotation, and the electric trolley all adopt AC motor frequency conversion stepless speed regulation, constant torque output, stable speed (especially at low speed), quick start or stop, speed digital display and preset.

The column rotation is divided into manual and electric. The slewing bearing adopts the products of domestic famous brand manufacturers, with high-precision gears, flexible rotation, and manual locking, safe and reliable.

The trolley adopts the standard railway track as the walking track, which is divided into two types: manual and electric. Manual is suitable for light-duty and small-moving manipulators, while electric is suitable for heavy-duty or large-moving manipulators.

The welding manipulator can be matched with a special welding positioner to realize one-time clamping of the cylinder body, and the two welding torches can weld the left and right sides at the same time, which greatly improves the processing accuracy and production efficiency.

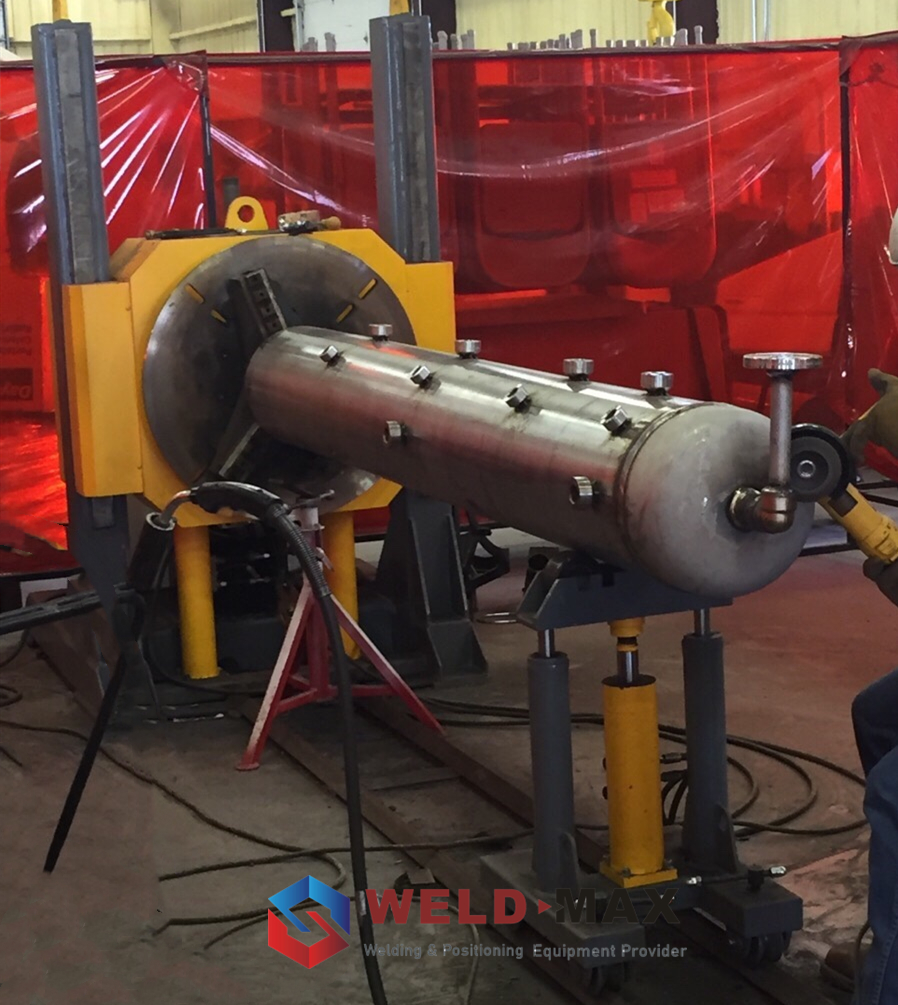

It can also be used with the welding rotator. The workpiece to be welded need to placed on the welding rotator. The operation of the welding rotator drives the operation of the cylinder, which can realize automatic welding.

Welding manipulator is used in conjunction with welding rotator

Welding Positioner:

The welding positioner is a machine that rotates and tilts the workpiece to place the weld on the workpiece at a favorable welding position. It is mainly used for turning and welding of non-long workpieces such as frame, machine base, flange, head, etc. It can also be used for assembly, cutting, inspection, etc.

The welding positioner can be equipped with welding machine power such as argon arc welding machine (wired or not filled), molten gas shielded welding machine (C02/MAG/MIG welding machine), plasma welding machine and other welding machine power sources and can be combined with other machines to form an automatic Welding system. The equipment is mainly composed of a rotating machine head, a displacement mechanism and a controller. The speed of the rotating machine head is adjustable, with an independent speed regulation circuit, and the DIP switch directly presets the length of the weld. The tilt angle can be adjusted as required.

So, how to make better use of so many types of positioners? This requires operators to know the operating specifications and make preparations:

One is to know the welding structure clearly, and the other is to know the condition of the equipment. For example, if the submerged arc welding equipment is used, flat welding is performed. If the workpiece has a certain slope or curvature, it needs to be turned into a flat welding position by a positioner. If the welding is performed manually, the position must be adjusted by a positioner to facilitate the smooth progress of the work and improve the welding quality.

Welding Rotator:

The welding rotator is a device that drives the cylindrical (or conical) weldment to rotate by means of the friction between the workpiece and the active roller.

Commonly used for welding inner and outer circumferential seams and inner and outer longitudinal seams of cylindrical workpieces, including base, driving roller, driven roller, bracket, transmission device, power device drive, etc. The transmission device drives the active roller, and uses the friction between the active roller and the cylindrical workpiece to drive the workpiece to rotate to realize displacement, which can realize the horizontal position welding of the inner and outer circumferential seams of the workpiece and the inner and outer longitudinal seams. The automatic welding equipment can realize automatic welding. , It can greatly improve the quality of welds, reduce labor intensity, and improve work efficiency. The welding rotator can also be used with manual welding or as a device for testing and assembling cylindrical workpieces.

Our customers will use the welding rotator with the manipulator more often. The roller drives the cylinder to run and realize automatic welding with the manipulator.

Our welding rotator can perfectly fit each customer’s work piece.

Weld-Max has a professional technical team and sales team, dedicated to giving customers better products and experience. We can customize equipment suitable for customer workpieces according to customer needs, and have an after-sales team responsible for solving various problems encountered in after-sales use. During the warranty period, we will promptly send replacement parts for customers if any parts are lost. After the end of the warranty period, we can still provide customers with free technical consulting services.

The equipment produced by Weld-Max is running smoothly all over the world, involving wind towers, marine engineering, pressure vessels, basic pipelines, steel structures, petroleum and other industries. Years of cooperation experience makes us more and more professional.

Send your message to us:

Post time: May-14-2021