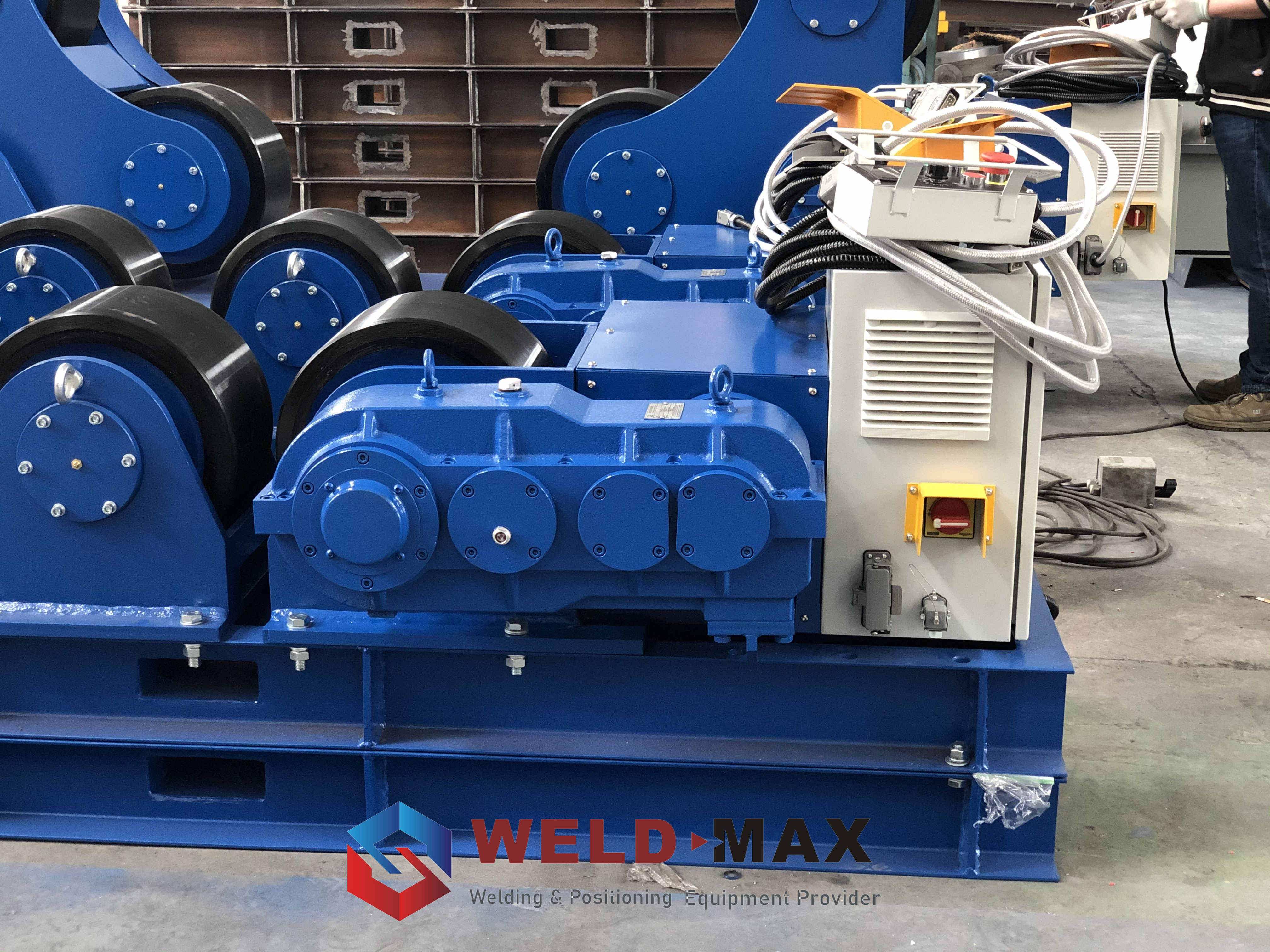

A customer from Canada ordered a set of welding rotator from Weld-Max for the first time last year. After using it for two months, the quality of the welding rotator has been recognized by the customer, which has improved their production efficiency, so they ordered another 60-ton conventional welding rotator.

The equipment has been completed and undergoes final commissioning, ready to arrange shipment.

The welding rotator is a kind of welding auxiliary equipment, which is used for welding the inner and outer circumferential seams and the inner and outer longitudinal seams of certain types of workpieces. A set of rotator is composed of base, driving roller, driven roller, bracket, transmission device, power device drive, etc.

The welding rotator is mainly used for cylindrical assembly and welding. If the height of the main and driven rollers is adjusted appropriately, the assembly and welding of the vertebral body and the segmental unequal rotation body can also be carried out. For some non-round and long weldments, if they are installed in a special ring clamp, they can also be assembled and welded on the welding roller frame. The welding roller frame can also be used with manual welding as a device for testing and assembling cylindrical workpieces. The use of the welding rotator can greatly improve the quality of the weld, reduce labor intensity, and improve work efficiency.

The adjustable welding rotator of Weld-Max consists of a driving wheel and a driven wheel. The active roller operation is driven by two motors respectively. Through the speed-regulating motor, the speed-regulating controller realizes stepless speed change through variable frequency speed regulation or electromagnetic speed regulation. The linear speed of the workpiece rotation is 6-60 meters/hour, which can meet the needs of manual welding, automatic surfacing welding, automatic submerged arc welding and other different welding needs, as well as various riveting of the workpiece. The distance between the main and driven rollers can be adjusted by bolt or screw to meet the welding requirements of workpieces of different specifications.

To achieve the smooth rotation of the weldment with stepless speed regulation, Weld-Max generally adopts two driving methods: DC speed regulation and AC frequency conversion speed regulation. Since DC speed regulation has the defects of high failure rate and high cost, AC frequency conversion speed regulation was chosen. With the development of electronic technology, AC frequency conversion speed regulation has been able to fully meet the needs of welding roller racks of various tonnages.

In order to make the adjustment of the roller spacing of the welding rotator convenient and reliable, and the combination is convenient, Weld-Max recommends the design of driving wheels separately, that is, each driving wheel is driven by an electric motor and a deceleration mechanism separately. However, attention should be paid to solving the synchronization problem of each driving wheel, so Weld-Max will try to use the same characteristics and tested to use in the selection of the motor and reducer structure. In the driving mode, it is recommended to use a set of driving sources, and each driving wheel motor is connected in parallel.

Send your message to us:

Post time: Mar-25-2021