With many years of production experience and sales services, Weld-Fab has good cooperation with foundation pipe manufacturers, wind power equipment companies, pressure vessel manufacturing companies, etc. all over the world.

Our team is constantly improving professional knowledge, learning and understanding technologies in various fields, and constantly improving the quality of after-sales service.

From the design to the final completion of each product, we pay great attention to the control of the details. Only by being accurate in every detail and laying a good foundation for the equipment, can the smooth operation of the equipment be guaranteed.

Today we will introduce the details of the Weldig Rotator.

After cutting and polishing the raw materials required by the welding rotator, they are welded to form the base part. After assembling the parts and ensuring that there is no problem with the installation, disassemble the parts for painting. Different colors can also be sprayed according to customer requirements, and the color card is provided by the customer.

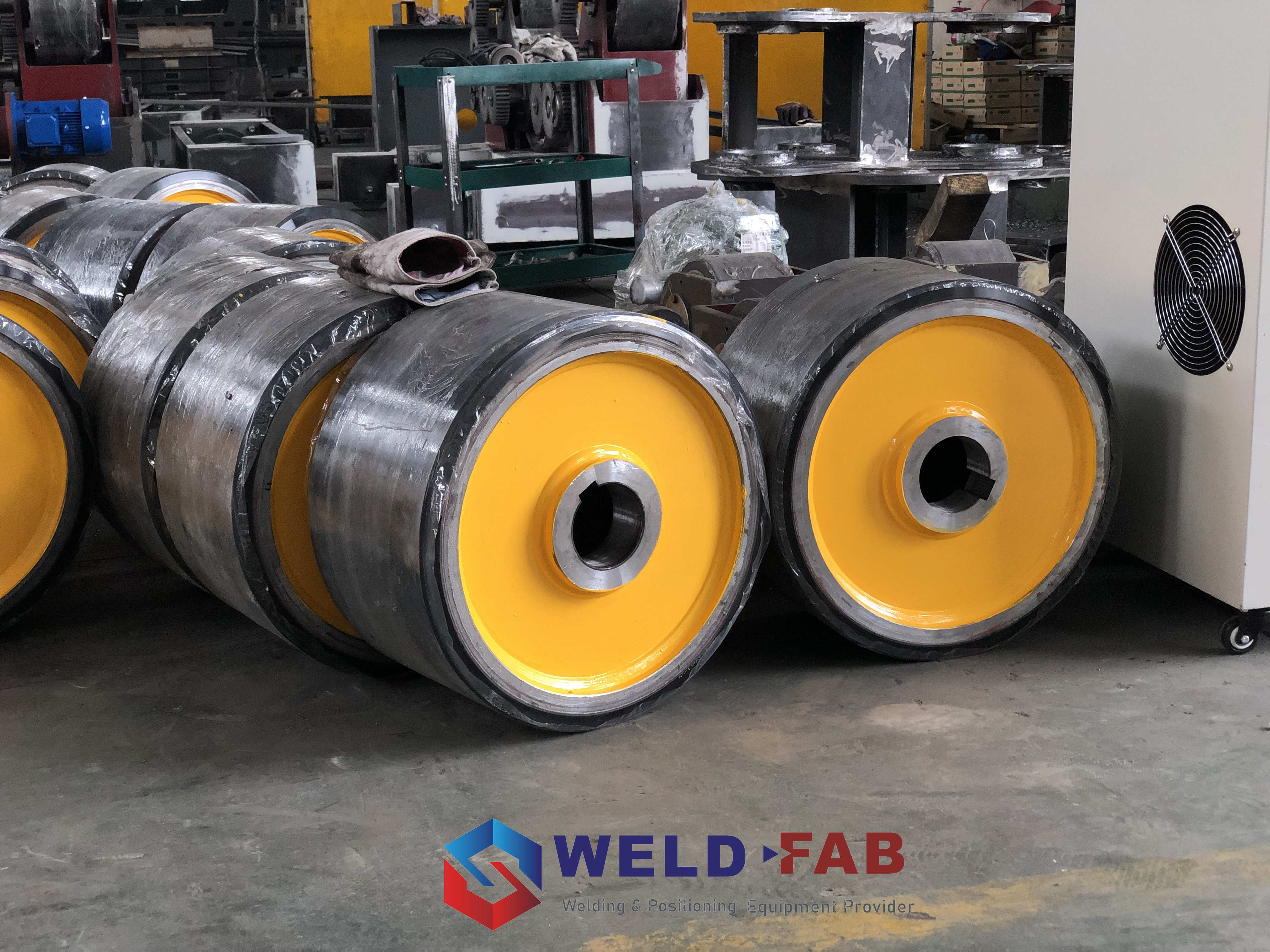

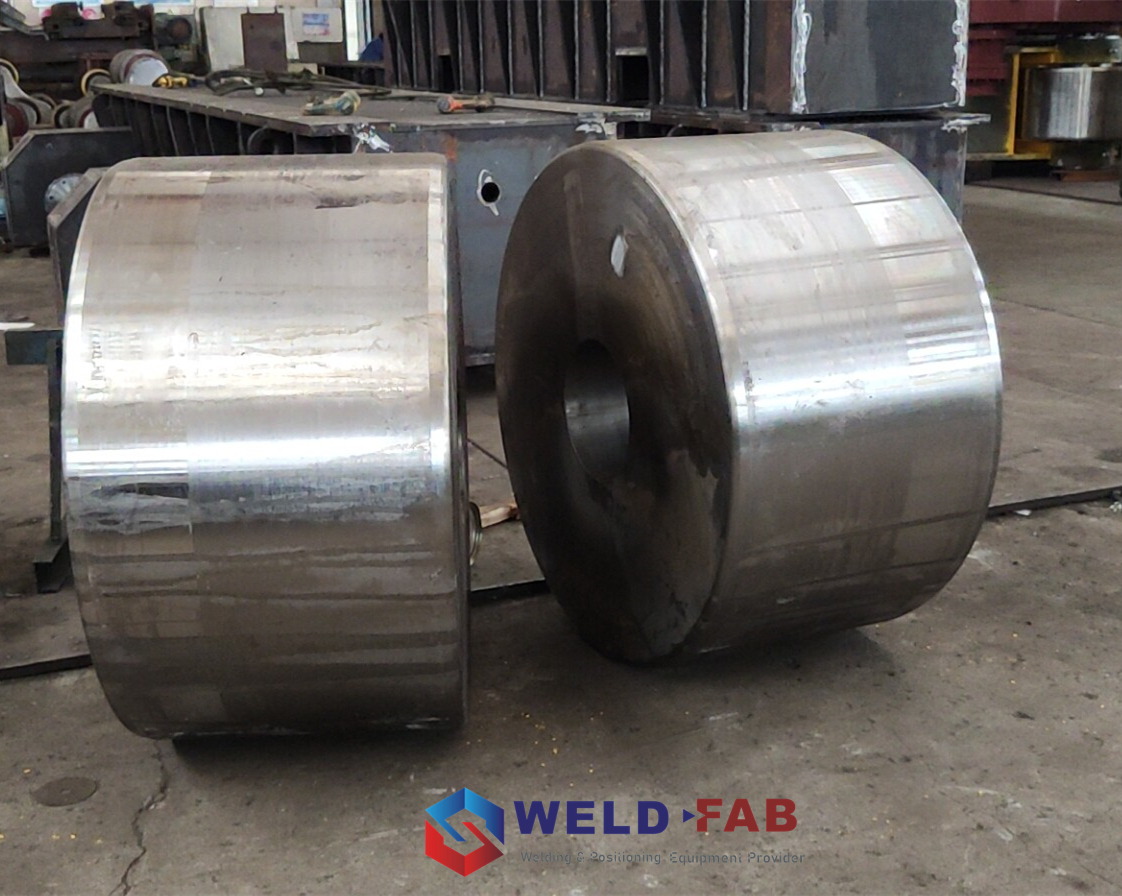

The roller adopts polyurethane wrapped steel core wheel. The polyurethane wheel can reduce the friction between the roller and the cylinder, so that the cylinder does not slip, and the polyurethane has the characteristics of wear resistance and high temperature resistance. Customers can also choose steel wheels according to their needs, according to the weight of the workpiece and the high temperature environment of the workpiece.

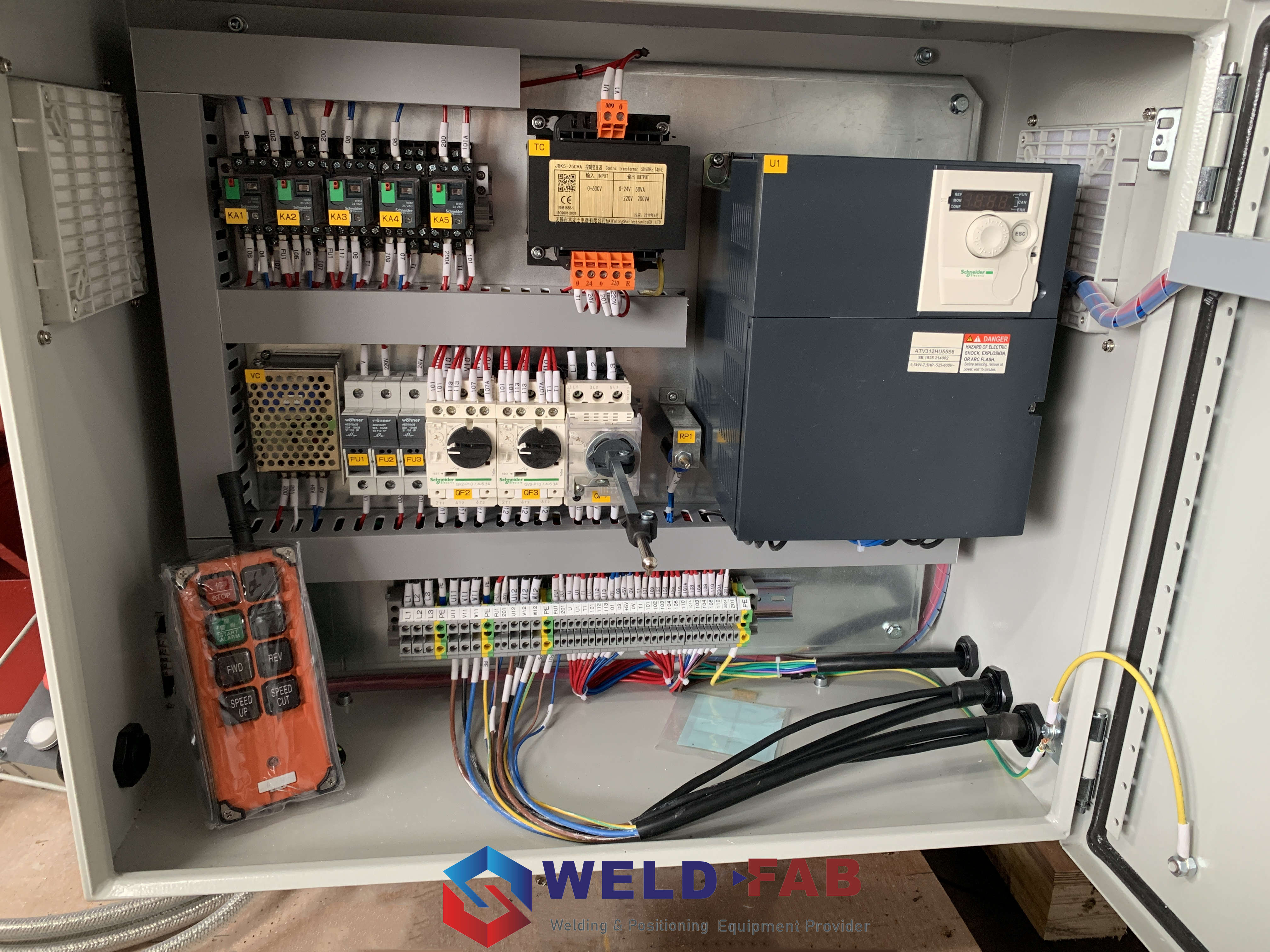

The electric control box of the welding rotator is clean and tidy, the lines are arranged in an orderly manner, and are equipped with electricity protection. All wiring are arranged in order and bundled at the end to ensure clear wiring.

The motor and control box of the welding rotator are protected by a cover to ensure safe use.

Holes are evenly arranged on the base of the welding rotator to facilitate the use of screws to adjust the size between the rollers.

The welding rotator will be cleaned before delivery, wipe off the dust and grease on the surface, and wrap the hand control box and foot control box with a protective film, and then put the welding rotator in a wooden box for packaging. The wooden box can protect the welding rotator from being squeezed and damaged by external force during transportation.

Send your message to us:

Post time: May-21-2021