Manufacturing Technology Of Welding Turning table

At present, in the machinery manufacturing industry, positioners with different functions are often used in the processing and manufacturing of some complex sheet metal riveting workpieces. The positioner is a special welding auxiliary equipment suitable for the welding displacement of the rotary work to obtain ideal processing position and welding speed. Each type of positioner is divided into several types according to its structural characteristics or functions, which are suitable for different shapes of workpieces, but most of the structures are complex and the workpiece loading and unloading process is tedious and wastes man-hours. It is not practical for processing some simple shape and structure workpieces.

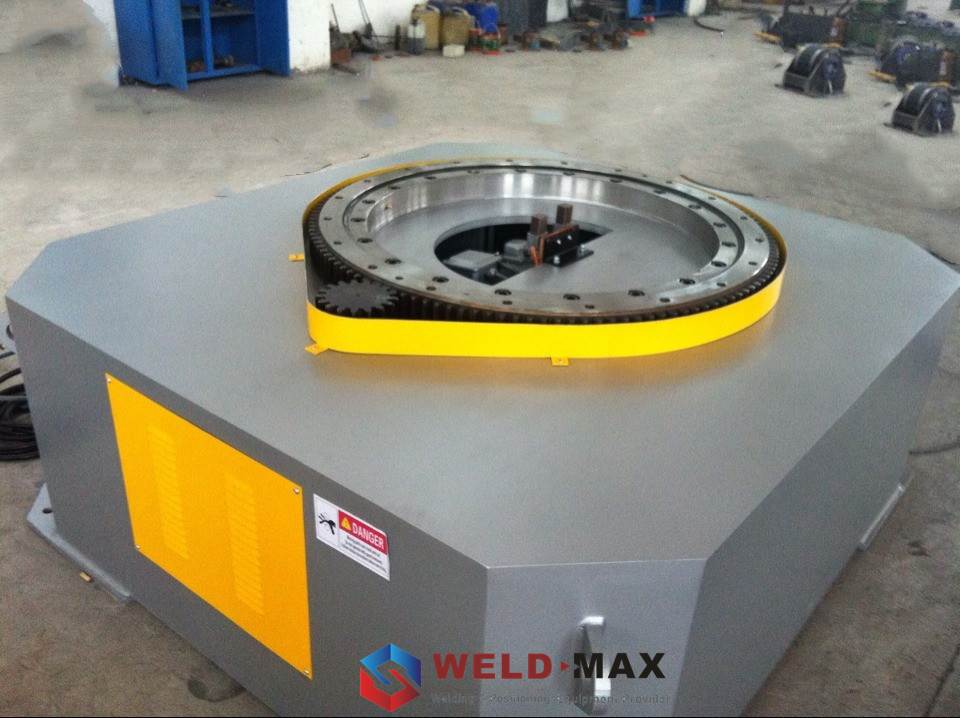

The purpose of the welding turning table produced by Weld-Max is to provide a welding positioner, which has a simple structure and can simplify the process of loading and unloading workpieces during production, thereby saving man-hours.

The Weld-Max welding turning table includes a base and a turntable. The base is connected below the turntable; the turntable includes a disk body and a support frame. The disk body is provided with a long installation groove. The support frame is installed on the disk body through a locking screw slot on.

The welding turning table also includes a flange plate and a supporting ring, the flange plate is connected under the plate body through a fixing screw, and the supporting ring is connected under the flange plate and arranged on the base.

The welding turntable also includes a reducer, a reducer and a motor. The reducer is connected with a flange. The reducer, the reducer and the motor are connected in sequence, located inside the base, and the motor is a variable frequency stepless speed regulation motor.

An exposed outlet is opened on one side of the base, and a shielding eave is provided at the exposed exit. The motor extends out of the base through the exposed exit and is installed under the shielding eaves. There are six supporting frames, which are evenly distributed around the center of the disc body. The supporting frame is arranged in an elongated ring shape, and the length is longer than the radius of the disc body.

The beneficial effects of the utility model rotary table designed by Weld-Max are: simple structure, low production cost; and adjustable position of each support frame, suitable for the production of various types of simple structure workpieces, greatly enhanced practicability; simplifying the process of loading and unloading workpieces thereby saving hours of production pieces.

Send your message to us:

Post time: Jun-25-2021